Comprehensive Tank Inspections by PTTG

At PTTG, our tank inspections are designed to ensure the longevity, safety, and performance of your water storage systems. Our detailed process identifies any issues and helps extend the life of your tank by offering proactive solutions. Below is a breakdown of what you can expect during our inspection process.

Capturing Vital Information

We begin by gathering essential details about your tank to provide a thorough inspection. Our team collects and documents specifics like tank type, capacity, material, and any unique configurations.

-

Full structural assessments, including ladders, platforms, and safety rails.

-

Function and current use (e.g., fire protection or potable water).

Recent inspection history and existing conditions.

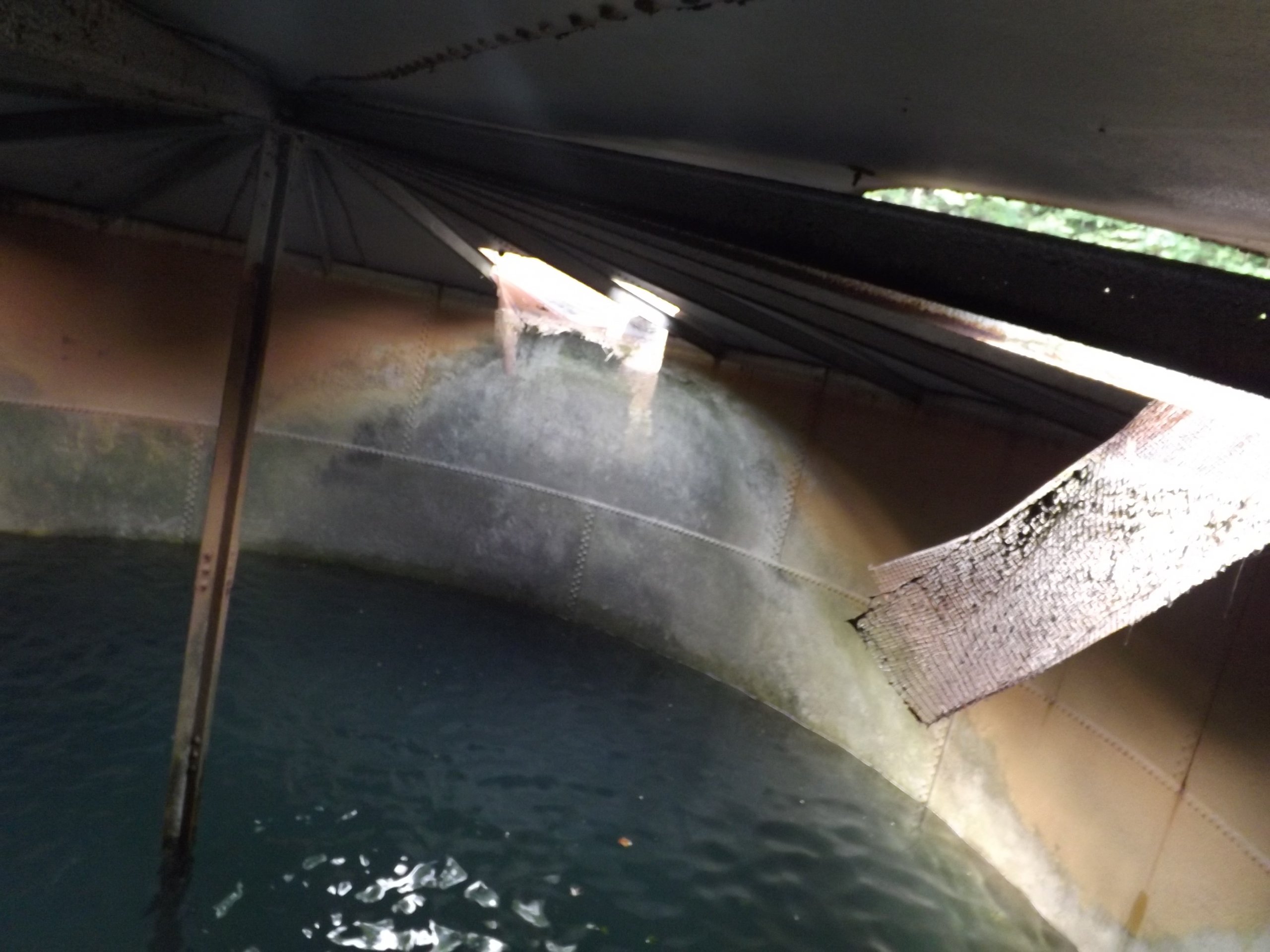

Evaluating Interior and Exterior Components

Our experts conduct an in-depth examination of both the tank's interior and exterior, focusing on coatings, structural integrity, and OSHA compliance. We look closely at key components that contribute to the safety and functionality of your tank.

-

Interior coatings (e.g., epoxy primer, polyurethane).

-

Ladders, platforms, and shell inspections.

Condition of vents, hatches, handrails, and ladders.

OSHA compliance for ladders and platforms.

Preventative Solutions

Any deficiencies found during the inspection will be noted, with preventative recommendations provided to avoid future issues. From simple repairs to major refurbishments, we help you plan the necessary steps to keep your tank in optimal condition.

-

Shell defects, manways, gauges, overflow, and drainage issues.

-

Recommendations for interior and exterior recoating.

Suggestions for cathodic protection and ladder upgrades.

Why Choose PTTG for Your Tank Inspections?

Our inspections go beyond just identifying problems; we offer long-term solutions to extend your tank's life and maintain compliance with safety standards. With a focus on proactive maintenance and customer satisfaction, we ensure your tank continues to perform at its best.